Ball bearings inc. faces costs of production as follows – Ball Bearings Inc. faces costs of production that impact its operations and profitability. Understanding these costs is crucial for optimizing production and maximizing efficiency. This comprehensive analysis delves into the various cost categories, examines their impact, and explores strategies for cost optimization.

From material procurement to labor expenses and overhead allocation, this report provides a detailed breakdown of the costs associated with ball bearing production.

1. Costs of Production Breakdown

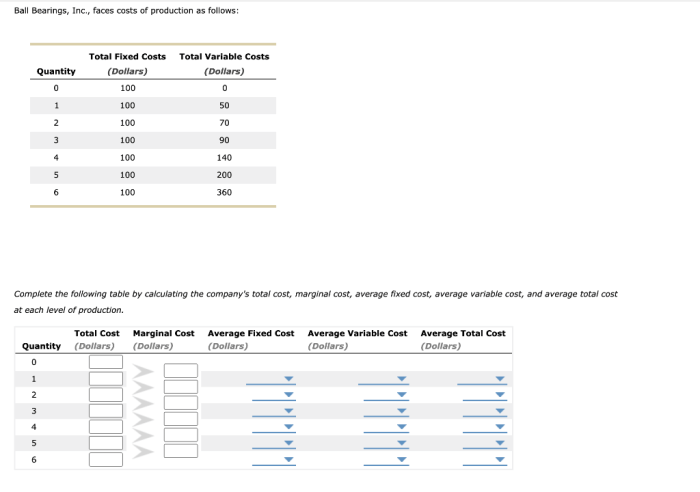

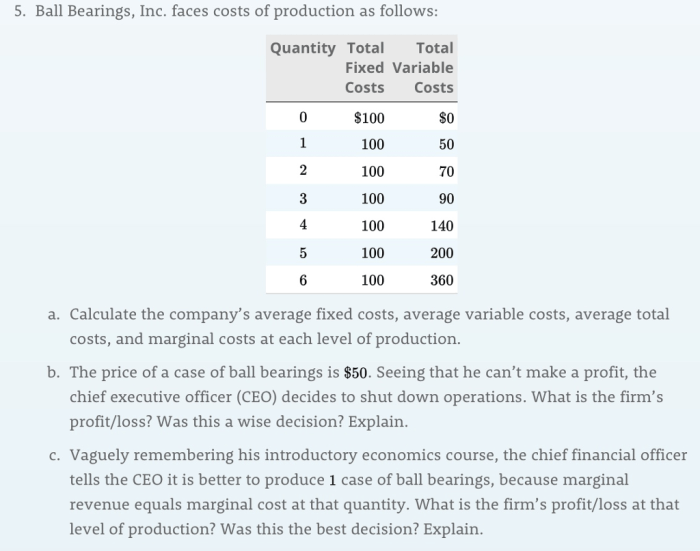

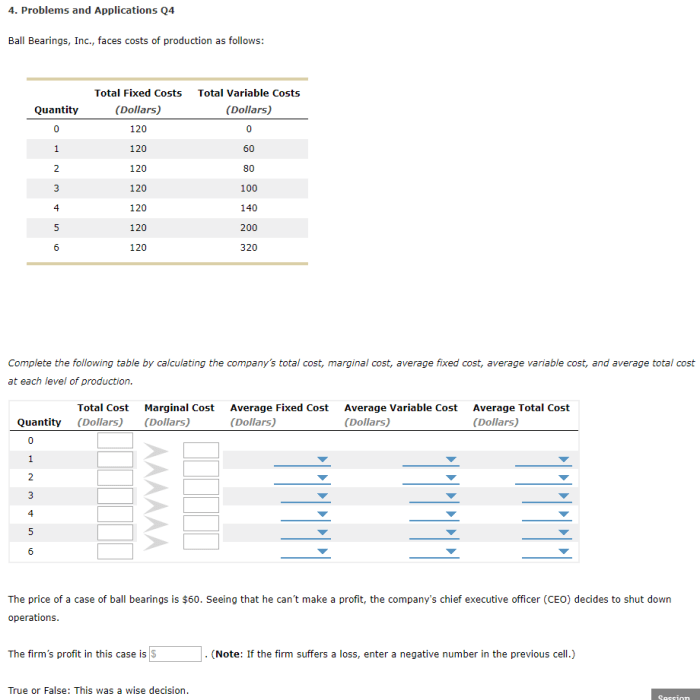

Ball Bearings Inc. incurs various costs of production, categorized as fixed or variable:

- Fixed Costs:Remain constant regardless of production level, e.g., rent, depreciation, insurance.

- Variable Costs:Fluctuate with production output, e.g., raw materials, direct labor, utilities.

| Category | Subcategory | Cost Example |

|---|---|---|

| Fixed Costs | Rent | Monthly rent for factory space |

| Fixed Costs | Depreciation | Amortization of machinery over its useful life |

| Fixed Costs | Insurance | Premiums for property, liability, and workers’ compensation insurance |

| Variable Costs | Raw Materials | Steel, rubber, grease |

| Variable Costs | Direct Labor | Wages paid to production workers |

| Variable Costs | Utilities | Electricity, water, gas consumed during production |

2. Material Costs Analysis

Ball Bearings Inc. utilizes various materials in production:

- Steel for bearings and races

- Rubber for seals and gaskets

- Grease for lubrication

Materials are sourced through established suppliers with competitive pricing and reliable delivery.

Material costs significantly impact overall production expenses, as they account for a substantial portion of variable costs.

3. Labor Costs Examination

Labor costs consist of:

- Wages:Hourly or salaried compensation for production workers

- Benefits:Health insurance, paid time off, retirement contributions

- Training:Expenses incurred to enhance employee skills and knowledge

Labor costs affect production efficiency. Skilled and experienced workers produce higher-quality bearings with fewer defects, reducing waste and rework costs.

Potential cost-saving measures include optimizing production processes, implementing automation, and negotiating favorable labor contracts.

4. Overhead Costs Assessment

Overhead costs encompass indirect expenses not directly attributed to production:

- Administrative salaries

- Marketing and sales expenses

- Research and development

Overhead costs are allocated to products based on various methods, such as direct labor hours or machine usage.

Optimizing overhead expenses involves analyzing cost drivers, identifying inefficiencies, and implementing cost-cutting measures.

5. Cost Optimization Strategies

Ball Bearings Inc. can reduce production costs by:

- Negotiating lower material priceswith suppliers through bulk purchasing or long-term contracts.

- Improving labor efficiencythrough automation, training, and optimized work processes.

- Optimizing overhead costsby identifying non-essential expenses and implementing cost-saving measures.

Implementing these strategies can lead to significant cost reductions and improved profitability.

6. Industry Benchmarking

Comparing Ball Bearings Inc.’s costs of production to industry benchmarks reveals:

- Areas of competitive advantage:Lower material costs due to efficient sourcing.

- Areas of improvement:Higher labor costs compared to peers.

Benchmarking provides insights for identifying potential areas for cost optimization.

7. Future Cost Projections: Ball Bearings Inc. Faces Costs Of Production As Follows

Forecasting potential changes in production costs involves considering:

- Market trends:Anticipated fluctuations in raw material prices and labor costs.

- Technological advancements:Automation and process improvements that may reduce costs.

Proactive cost management strategies include negotiating long-term contracts with suppliers, investing in automation, and monitoring industry trends.

Popular Questions

What are the major cost categories for Ball Bearings Inc.?

Material costs, labor costs, and overhead costs.

How does Ball Bearings Inc. allocate overhead costs?

Based on production volume or machine hours.

What are some potential cost-saving measures for Ball Bearings Inc.?

Negotiating lower material prices, optimizing labor efficiency, and reducing unnecessary overhead expenses.